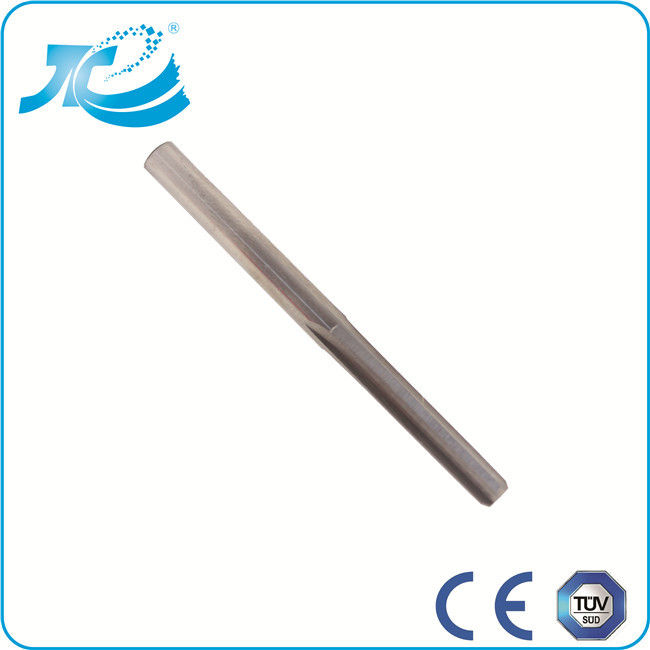

Detailed Product Description

| Product Name: |

Carbide CNC Milling Chucking Reamer / Cutting Tool Tungsten Steel Chuck Drill Reamer |

Hardness: |

55/60/65 Degree |

| Cutting: |

2-13mm |

Flute: |

Four |

| Material: |

Tungsten Steel |

Coating: |

TiAlN,TiCN TiN And ARCO |

| Customizable: |

Yes |

Application: |

CNC Milling |

| High Light: |

micro reamers, extra long reamers |

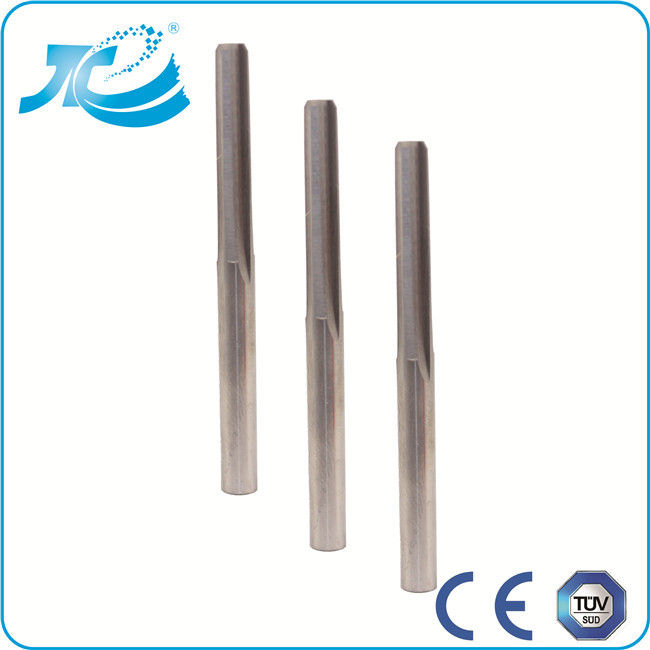

Carbide CNC Milling Chucking Reamer / Cutting Tool Tungsten Steel Chuck Drill Reamer

Description

1. Reamers are precision cutting tools used to enlarge existing holes smoothly and accurately by removing a small amount of metal. Reamer geometry varies widely, having four or more flutes, spiral or straight, and left or right hand cut.

2. Reamers are used to rough or finish ream predrilled, punched, or die-cast cavities for improved size, roundness, straightness, and surface finish.

3. Though straight flute reamers are still popular, there are many advantages to spiral flute construction. Particularly in smaller sizes, spiral flute reamers can be manufactured more accurately and result in a considerable cost savings.

4. High Speed Steel Straight Flute Metric Hand Reamers are designed for extreme accuracy and are used by hand for final sizing of drilled holes.

5. The square shank and fits in a tap wrench. Both styles of Hand Reamers have a ground starting taper on cutting end for easy entry.

We use 100% original raw material, the micro grain tungsten carbide powder and cobalt powder(from German)to make the carbide rod, hardness can be 92.5-94.0(HRA), and T.R.S. is 4200-4800(N/mm2), this carbide rod can ensure the end mills with very strong abrasive resistance and impact strength.

Original raw micro grain material, high hardness and T.R.S.

1, Co: 10-12%, WC: 88-90%,

Grain size: 0.4μm,

Hardness: 92.5-94.0 HRA,

T.R.S.: 4200-4800 N/mm2,

Density: 14.3-14.8 G/cm3

2, We got 250T Extruder, 10MPa Overpressure Sintering Furnace-Vacuum

Dewaxing, these two equipments are very very important for manufacture and high quality carbide rods.

3, We use our own carbide rod for 90% of cutting tools.

4, We have introduced advanced CNC grinding machines in operating,Rollomatic,Schneeberger from Switzerland, ANCA from Australia, Zoller from German,KEYENCE from Japan,set up(Japan FANUC, brother processing center) tool laboratory test cut.Our technology from Taiwan. Guarantee high precision and good performance.

5, Helix Angle: 38-42 °(we could do 4 of them are 37°)

Diameter of cutting edge: 2.0-13.0mm

Diameter of rods: 24-105mm

Length: 49-151mm

Cutting Form: Ball nose, Corner Radius, Taper Flute, etc.

Flutes No.: 4

Super coating

TiAN,TiCN TiN and ARCO ,

improve tool life, reduce the coefficient of friction.

Applications

Copper, Aluminium Alloy , Cast Iron, Carbon steel, Tool steel,

Mould steel, Die steel, Stainless steel, Plastic, Arcylic, etc

Price Performance Ratio

From tungsten powder to end mills, that's the reason of our competitiveness!

Make sure about each piece end mill has a good quality,high precision and good performance.

More discount will be offered according to exact quantity.

Welcome to be our agents, OEM is also available.

Specifications:

|

Diameter/D1

|

Flute Length/L1

|

O.A.L/L3

|

Shank Dia/D2

|

Flute

|

|

2.0

|

11

|

49

|

24

|

4

|

|

2.1

|

11

|

49

|

24

|

4

|

|

2.2

|

12

|

53

|

26

|

4

|

|

2.3

|

12

|

53

|

26

|

4

|

|

2.4

|

14

|

57

|

28

|

4

|

|

2.5

|

14

|

57

|

28

|

4

|

|

2.6

|

14

|

57

|

28

|

4

|

|

2.7

|

15

|

61

|

32

|

4

|

|

2.8

|

15

|

61

|

32

|

4

|

|

2.9

|

15

|

61

|

32

|

4

|

|

3.0

|

15

|

61

|

32

|

4

|

|

3.1

|

16

|

65

|

35

|

4

|

|

3.2

|

16

|

65

|

35

|

4

|

|

3.3

|

16

|

65

|

35

|

4

|

|

3.4

|

18

|

70

|

40

|

4

|

|

3.5

|

18

|

70

|

40

|

4

|

|

3.6

|

18

|

70

|

40

|

4

|

|

3.7

|

18

|

70

|

40

|

4

|

|

3.8

|

19

|

75

|

43

|

4

|

|

3.9

|

19

|

75

|

43

|

4

|

|

4.0

|

19

|

75

|

43

|

4

|

|

4.1

|

19

|

75

|

43

|

4

|

|

4.2

|

19

|

75

|

43

|

4

|

|

4.3

|

21

|

80

|

47

|

4

|

|

4.4

|

21

|

80

|

47

|

4

|

|

4.5

|

21

|

80

|

47

|

4

|

|

4.6

|

21

|

80

|

47

|

4

|

|

4.7

|

21

|

80

|

47

|

4

|

|

4.8

|

23

|

86

|

52

|

4

|

|

4.9

|

23

|

86

|

52

|

4

|

|

5.0

|

23

|

86

|

52

|

4

|

|

5.1

|

23

|

86

|

52

|

4

|

|

5.2

|

23

|

86

|

52

|

4

|

|

5.3

|

23

|

86

|

52

|

4

|

|

5.4

|

26

|

93

|

57

|

4

|

|

5.5

|

26

|

93

|

57

|

4

|

|

5.6

|

26

|

93

|

57

|

4

|

|

5.7

|

26

|

93

|

57

|

4

|

|

5.8

|

26

|

93

|

57

|

4

|

|

5.9

|

26

|

93

|

57

|

4

|

|

6.0

|

26

|

93

|

57

|

4

|

|

6.1

|

28

|

101

|

63

|

6

|

|

6.2

|

28

|

101

|

63

|

6

|

|

6.3

|

28

|

101

|

63

|

6

|

|

6.4

|

28

|

101

|

63

|

6

|

|

6.5

|

28

|

101

|

63

|

6

|

|

6.6

|

31

|

110

|

69

|

6

|

|

6.7

|

31

|

110

|

69

|

6

|

|

6.8

|

31

|

110

|

69

|

6

|

|

6.9

|

31

|

110

|

69

|

6

|

|

7.0

|

31

|

110

|

69

|

6

|

|

7.1

|

31

|

110

|

69

|

6

|

|

7.2

|

31

|

110

|

69

|

6

|

|

7.3

|

31

|

110

|

69

|

6

|

|

7.4

|

31

|

110

|

69

|

6

|

|

7.5

|

31

|

110

|

69

|

6

|

|

7.6

|

31

|

110

|

69

|

6

|

|

7.7

|

31

|

110

|

69

|

6

|

|

7.8

|

31

|

110

|

69

|

6

|

|

7.9

|

31

|

110

|

69

|

6

|

|

8.0

|

31

|

110

|

69

|

6

|

|

8.5

|

31

|

110

|

69

|

6

|

|

9.0

|

33

|

110

|

69

|

6

|

|

9.5

|

33

|

110

|

69

|

6

|

|

10.0

|

36

|

110

|

69

|

6

|

|

11.0

|

41

|

142

|

95

|

6

|

|

12.0

|

44

|

151

|

105

|

6

|

|

13.0

|

44

|

151

|

105

|

6

|

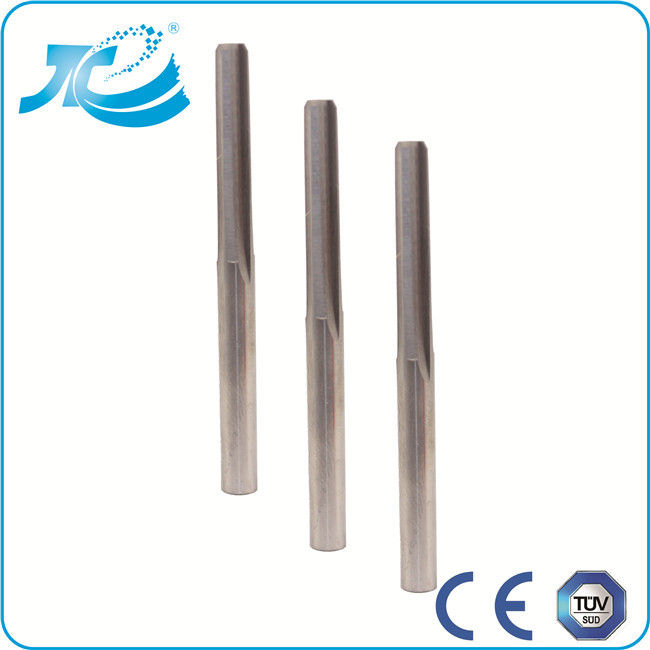

Products display